Fuel safety assurance is directly related to the safety of weapons and equipment, and it is one of the key points in the safety management of our military. Storage tanks and boxes are prone to combustion and explosion due to accidental incidents (such as: ammunition attacks, terrorist activity strikes, and personnel misoperation, etc.), especially the fuel tanks of ground equipment, which are highly susceptible to damage from fragments of various explosives and shockwaves, leading to rapid leakage, combustion, and explosion. Statistical data indicate that in modern local wars, the rapid fuel leakage and 'secondary explosion' caused by the fire attack on equipment fuel tanks or storage tanks are the main reasons for equipment damage and casualties。

Technical innovations in four major areas: principles of explosion protection, innovative product structures, high polymer raw materials, and high-speed ultra-high cavity fully automatic production systems. Have obtained multiple national invention patents。

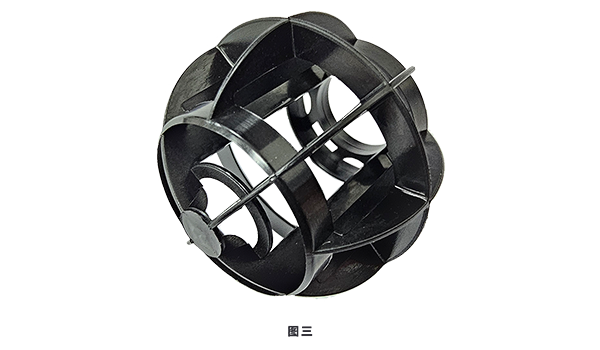

Structural Principles:

①After the combustion wave comes into contact with the multifaceted hollow spherical blast-resistant material, some of the heat is absorbed by the material, reducing the temperature of the flame;

②Free radicals in the flame are destroyed upon collision with the material, reducing the number of free radicals and decreasing the flame intensity;

③When the flame passes through the porous blast-resistant material, it is divided into a large number of small flame streams, making the flame front discontinuous;

④When the shock wave encounters the small chambers within the blast suppression material, it undergoes continuous reflection, transforming part of the shock wave energy into plastic deformation of the material. When the energy of the shock wave is high, its impact shear effect causes the spherical blast suppression material to transition from plastic deformation to structural damage, thereby attenuating the shock wave。

Technical Form:

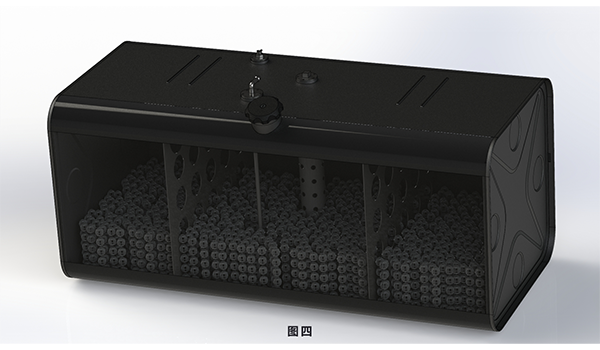

Multifaceted hollow spherical blast-resistant materials are made with high-quality material skeletons and unique nanofiber auxiliary materials. The product is widely applicable to the safety protection of hazardous chemical fuels such as gasoline, diesel, kerosene, and natural gas under extreme conditions, with high-strength energy absorption without decomposition. The optimized multifaceted hollow sphere structure directly targets the explosion-proof mechanism of fuel, cutting off the transmission path of combustion and explosion pressure waves at the millisecond level, completely eliminating the core hazards of ignition and detonation caused by artillery and gunfire. It effectively reduces the evaporation of oil and gas, reducing the conditions for ignition and explosion caused by open flames and static electricity. It effectively eliminates fuel surge, preventing the chances of explosion due to accidental overturning and violent impact. It withstands high-temperature baking and allows for welding repairs with fuel to restore equipment functionality。